automaTech INDUSTRIAL AUTOMATION SYSTEM (AIAS)

Introduction

A constant demand for efficient, economical, and energy aware systems inspired a group of engineers to start a project which would combine these qualities into a single solution for industrial automation. An idea grew into a prototype, and the prototype was the foundation for the company automaTech OG. Our company is built on huge know-how in areas computer engineering, electrical engineering, industrial automation and industrial control. Using state-of-the-art technologies we achieved a goal of bringing affordable and highly dependable systems to small and midsize companies. Using our approach we are able to achieve short and precise project plans, and provide easy upgrade strategy for all projects.

Keywords: industrial automation, sequential process automation, computer engineering, efficiency, cost reduction, reliability.

Motivation

The automaTech OG industrial automation system (AIAS) is applicable on all facilities for sequential industrial processing. The system was created to solve problems in grain transportation and storage facilities. Problems our customers were faced were:

- non-flexible and static systems,

- no upgrade possibility,

- no support or poor support, and instruction manuals,

- unintuitive user interface,

- large software latencies,

- poor safety and security measures,

- frequent failures of the system, and

- energy unawareness.

During the development, we recognized the same problems with other similar industrial facilities and decided to build a system capable of running any plant with similar characteristics, and still solve the above stated problems.

What is the current state of technology?

Technology has been advancing rapidly in recent years. Most manufacturers of industrial computer systems release new products every few months. These products are the result of these companies’ R&D efforts and they represent the latest technical trends and possibilities. Companies that use these products to develop final applications, still tend to neglect new technologies. In order to avoid training costs and the change of every day routine, developers stick with legacy technologies, sometimes even few decades old. Such practices bear following drawbacks:

- unnecessary additional costs,

- security risks,

- longer time to market,

- lack of environmental awareness.

What do we offer?

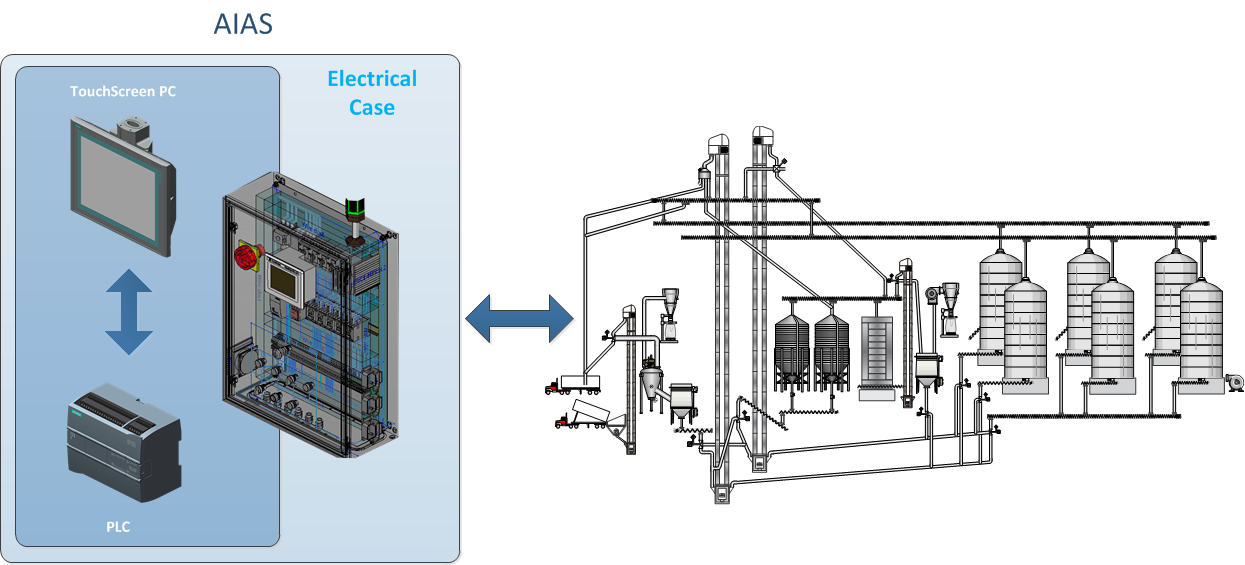

The automaTech OG industrial automation system (AIAS) represents a mixture of existing and upcoming standards, satisfying former and introducing future capabilities. The system consist of an industrial computer for automation of electromechanical processes, called Programmable Logic Controller (PLC) and a general purpose computer for industrial environments with an integrated touch screen. The PLC is directly connected to electromechanical machines controlling their behavior based in accordance with the programmed algorithm. The general purpose computer is used as a bridge between the PLC and the user, via integrated touch screen.

Figure 1 illustrates the simplified overview of the AIAS, with a grain storage facility as an example of the industrial process. All physical components and their respective role in the system are represented. The second major part of the AIAS is a corresponding software on each of the components listed above.

Examples of AIAS target systems:

- grain transport and storage facilities,

- milling facilities ,

- stock food production facilities,

- wood pellet production facilities, etc..

Figure 1 AIAS Overview

Figure 2 shows a simplified program structure of the AIAS PLC and HMI application which are executed via the touch screen PC. Both parts are designed with the specific task to of reducing eventual human errors to minimum.